Ops Constructability Review Delivers Exceptional Value by Eliminating Unnecessary Equipment and Streamlining Process Efficiencies

The Challenge

A major oil refiner in the U.S. was in the planning phase of a project to commission a new Naphtha Distillation Unit utilizing existing equipment in combination with adding new equipment. The existing workforce in this area in the refinery was well-versed in the normal operating duties of the area

but did not have the operations experience to successfully execute a major construction/commissioning project.

The Solution

CruzAlta provided a seasoned operations professional with a safety-focused culture, years of field-earned knowledge and practical operating philosophies to provide a streamlined focus and to highlight and correctany deficiencies in the project.

We attended 3D model reviews at the engineering firm and identified items that would have impacted the project, such as operability interferences between piping and structural steel, as well as proper-sized drains to

accommodate faster shutdown/cleanup activities.

P&ID reviews identified several operability/control issues with the original design that required control valve relocation, instrumentation relocation or isolation issues that would have impacted the site’s ability to perform maintenance activities.

Identified cost-saving measures such as reviewing unit rundown temperature parameters to ensure downstream unit feed temperature is optimized to improve the efficiency of the unit receiving our product rundowns.

The Results

The identification of equipment not needed for the project has resulted in an estimated $3MM to $5MM savings in cost. The flip side of our participation is

we have identified items which have required further engineering refinement, resulting in a $2MM to $4MM expense from the engineering firm. The client is happy for the trade-off as the discovery during the engineering review resulted in a lower cost than having to re-engineer the issue during construction.

Identifying process efficiencies has resulted in a savings of $1MM annually. This is a conservative estimate as operating conditions and refinery fuel costs are very fluid. The ability to recover preheat in the downstream units

is difficult to quantify, but it is a definite savings in the unit fuel requirement for heat in the process furnaces.

RELATED ARTICLES

Special Operations Team Enhances Site's Operator Training, Resulting in Increase in Goals Achieved

The Challenge

To support the operation of a new grassroots facility, the client hired and trained...

READ MORE →A Craftsman Toolbox: CruzAlta's Turnaround Management Consulting

.png?width=352&name=CAPE%20%20(1).png)

CruzAlta’s Turnaround (TA) Management consulting program is quickly gaining industry attention...

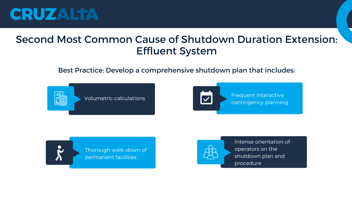

READ MORE →Effluent Management

In our previous blog, we introduced the top four turnaround delays and more deeply explored the #1...

READ MORE →

LEAVE YOUR COMMENT